TIRE FAILURE FROM FOREIGN OBJECTS

By

Charles C.

Roberts, Jr. Ph.D. P.E.

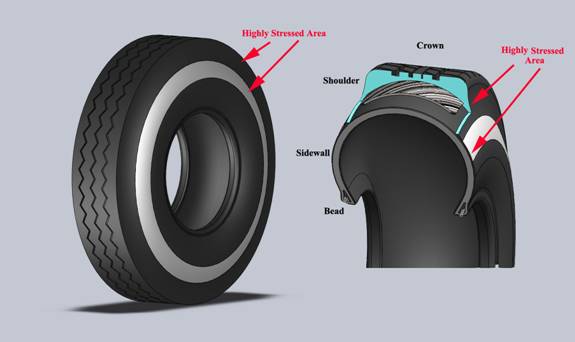

There are a variety

of failure modes for automobile tires such as bead failure1, impact

failures, defective manufacturer2, improper installation, wear out, and

under-inflation3. The failure mode from under-inflation can be as a

result of tire penetration by a foreign object. Figure 1 is a drawing of a

typical automotive tire. Foreign object penetration typically occurs in the

crown area of the tire, through the tread, however it is not unheard of to

discover a foreign object lodged in the upper sidewall or shoulder area. The

penetrating object may cause under-inflation of the tire, but not always. If

the penetrating object self seals, little or no air may escape from the tire.

If air does escape such that the tire operates under-inflated, failures can

occur at the highly stressed areas as a result of over-flex of the rubber.

Figure 1

Figure 2

Figure 2 is a view of

a Phillips head screw imbedded in the tread of an automobile tire. Initially this screw became partially engaged

in the tire and was not perpendicular to the tread, as indicated by the oval

shaped deformation to the head. Eventually it worked its way into the tire,

causing penetration and providing a path for air leakage. Approximately 20% of

the tread remained on this tire, facilitating the penetration of the screw into

this tire. Rubber dust inside the tire confirmed that the tire had operated for

a period of time under-inflated and eventually failed.

A tubeless tire valve stem attached to an air pressure tank at low

pressure can be used to determine if the penetration leaks. Press the valve

stem against the hole on the inside of the tire and check for leakage with a

soap solution. In this case, it leaked, suggesting that the screw was the likely

cause of under-inflation of the tire. In some cases the tire can be re-inflated

on the original rim and checked for leakage.

Figure 3

Figure 3 is another

example of a screw penetration into a tire that has resulted in the head of the

screw being worn away, as shown in Figure 4. This tire showed little evidence

of under-inflation, suggesting that self sealing occurred.

Figure 4

Figure 5

Figure 5 shows the

impression of a nail in a tire tread. This nail self sealed but was eventually

ejected, causing air leakage and eventual failure of the tire.

Figure 6

Figure 6 shows a tire

plug that did not seal properly, used to repair a tire which continued to leak,

resulting in an under-inflated tire related failure.

Under-inflation of

tires can cause excessive flexing of sidewalls, resulting in tread separation

or sidewall failure. This can cause loss of control of the vehicle and an

accident. It is not unusual for analysts to opine that a tire is defectively

manufactured after examining a tread separation or sidewall failure when the

underlying cause is under-inflation as a result of foreign object penetration.

References:

1. Roberts, Charles, Jr., “Tire

Failure Analysis – Bead Failure,” Claims Magazine, January 2000, p33.

2. Roberts, Charles, Jr., “What to Look for

in Firestone Tire Failures,” Claims Magazine, September 2000, p14f.

3. Roberts, Charles, Jr., “Automobile

Tire Failure Analysis – Under-inflation,” Claims Magazine, November 2000, p34.